The fashion industry is growing larger each day. Fashion has always been a fluid field with different styles, trends, garments depending on timeline, seasonality and region. This is why quality assurance in fashion has a long history, legacy and concepts as well.

Every quality control methodology has certain guidelines and principles to follow. For instance, adopting the correct statistical quality control method and using the right quality management tools is of utmost importance in ensuring smooth and successful production.

While most designer outfits are created after many days, even weeks, of planning and crafting a perfect outfit. These pieces are typically made for celebrities or fashion shows, and they’re only meant to be worn on the runway. Conversely, apparels and garments mass-produced and sold to the public following an entirely different process

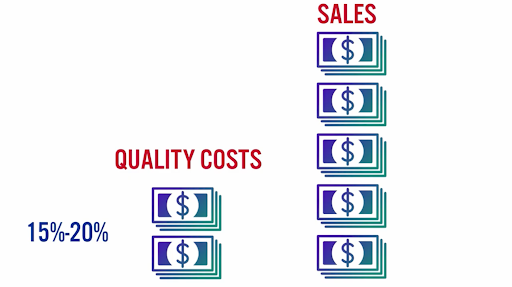

Quality costs

Quality costs involve the process of preventing, finding and correcting defective apparels or garments within the chain of production. Such costs can add up to a substantial amount which can range between 15% to 20% of sales.

Most of these expenses are wholly unnecessarily and can be mitigated. Effective quality assurance aims to bring down quality costs by significantly reducing or even completely avoiding such expenses.

Total quality cost

Total quality costs consist of the actual product costs and what the reduced costs amount to should there be no defects. This consists of 3 categories:

Failure costs

This involves both internal and external failures. For example, internal failures consist of reworking defective products or even fabric waste due to inefficient processes. External failures could involve customer complaints, product exchanges, refunds or even product damage due to poor packaging.

Appraisal costs

These are the costs incurred to maintain quality levels such as process controls, assessing incoming materials, performing the final inspection and more.

Prevention costs

The costs that are incurred to minimise failures such as quality planning, training employees and establishing apparel specifications.

Apart from reducing costs, why is quality assurance an important part of the fashion production process?

The competitive nature of the fashion industry means that each garment has to pass certain quality assurance standards. This is true even for brands with a fast fashion focus.

Return on investment

When a company begins to produce clothes on a large scale, they must ensure that their clothes are durable with a reasonable shelflife, otherwise, customers aren’t going to make repeated purchases.

Clothes tend to be mass-produced in factories to reduce costs and drive quantity. Even in fashion boutiques that produce small batches of clothes in-house, quality assurance is still essential in their production process, since a single defect can end up causing problematic issues such as refunds or a drop in trust, which reduces the overall return on investment. That’s why learning about quality control is crucial for any fashion professional.

Considerations such as speed, quality and profitability come into play when it comes to revenue generation. After all, proper quality control in fashion should grow overall revenue on top of reducing quality costs.

On-time production and delivery

An advantage of a well-maintained quality assurance process helps to ensure that your products are delivered on time. With reduced defects, product time can be kept efficient, which leads to on-time delivery of your products to customers.

Maintaining a good reputation

Quality checks don’t just help a company to make good clothes, they are also essential to building the reputation of that company. Clothes are everyday items that are constantly demanded by consumers. If a clothing brand releases a batch of products that follow a poorly designed production process or if apparels aren’t checked thoroughly, there is always a possibility of delivering defects.

Consumer considerations

When people buy clothes, they are looking for garments that are stylish and trendy while also being practical. The bulk of a person’s wardrobe is going to be filled with clothes that they use in their daily lives. That’s why quality is one of the defining factors of any good piece of clothing. Whether you are selling directly to consumers or supplying to retailers, having product defects ultimately harms the trustworthiness of your brand.

A smooth production process

While fashion designers have to understand deeply the essentials of textiles, sketch and design clothes that fit predefined quality standards. The process of assessing quality assurance in fashion comes with the goal of ensuring that there are no hiccups in the production process.

A lack of quality erodes trust, leads to refunds and increases the overall costs of holding stock. This is why many companies choose to hire individuals who have thorough knowledge in this area, aka the quality assurance manager.

For instance, are the buttons sewed on correctly? Do the zips work? Quality checks like these are absolutely critical in the factory where thousands of apparels are produced each day. It is wholly essential to understand the proper methods of quality assurance since one seemingly minuscule error could lead to irregularities in the production process.

Yet, for large scale factories, it is near impossible to check every piece of garment produced.

How is quality assurance in fashion carried out effectively then?

There are a couple of aspects that need to be monitored in order to make a good garment. Some of these factors depend on trends that are based on popularity rather than stringent controls, while other factors need a deft hand and thorough knowledge of the minimum requirements.

Generally, a few of the main factors that a person needs to know when it comes to quality assurance are listed below:

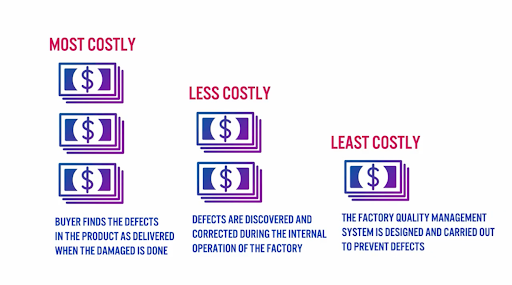

The impact on quality costs based on different scenarios

Defects discovered by the buyer

Well, a large portion of quality costs are brought by defects. Considering the damage in buyer trust alongside the logistical costs that come along with exchanges or refunds, such expenses peak when defective products reach the buyer. In this scenario, the damage is already done.

Defects discovered during internal operations

A well-equipped quality assurance team needs to identify and prevent defects during the production process. By discovering and correcting defects internally, costs associated with the product can be significantly reduced.

Leveraging a well-designed quality management system

The least costly method would be to implement a well-designed quality management system that allows defect-free production. This method requires a detailed study of existing practices and identifying areas that require adjustment.

Each fashion brand has its processes in place to prevent and check whether or not its apparels pass quality standards. In order to learn about all these details, a quality assurance specialist needs to participate in the necessary fashion course to equip themselves with the knowledge and methodologies of effective quality control.

However, the tough part of getting this knowledge is that there aren’t many short-term offline courses that allow you to enhance your knowledge in this area. Additionally, a person that has already completed a degree in a similar field might not want to go back to take up another certificate. One possible solution to this issue is to partake in a fashion quality assurance course.

Essential skills that a fashion quality assurance professional need to know

A skilled quality assurance manager in the fashion industry should have a strong foundation in being able to inspect and detect fabric defects, manage different colours and ensure that garments fit well when evaluating points of management.

Crucial aspects of quality assurance involve the technical know-how of utilising the right quality management tools, leveraging statistical quality control, evaluating the condition of the factory and more. Due to the huge volume of garments produced in a factory every day, statistical sampling is an important skill set needed to perform one’s tasks effectively. Yet, other techniques such as apparel colour management and understanding different points of measurement are needed to complement such a skill set if one desires to specialise in the fashion industry.

When performing the final inspection, it is imperative to have a strong foundation in understanding sewing, sizing and colour defects. Without these essential skills, the inspection report may not be accurate. A strong foundation in fabrics, stitches and seams are essential to identify suitable testing protocols based on the apparels produced as well as the needs and requirements of the factory.

Is the colour of the apparel accurate? Are the garments stitched properly? These are some questions to evaluate during any on-ground inspection.

From a management point of view, improving the capability of a fashion brand’s business processes effectively leads to improved profits and cost reduction. When considering the betterment of the fashion production process, the lean process and the six sigma methodology is able to improve the overall fashion production process.

How an online fashion course can help fashion industry professionals ensure that their garments are up to the standard.

An effective online fashion course can be incredibly useful to any designer or fashion industry professional that wants to ensure that their apparels and garments meet stringent quality standards. Additionally, being knowledgeable in this particular area of quality checks enables designers to better contribute to the brand.

Enhancing your knowledge in the sphere of fashion quality assurance will help you better understand the production process, reduce defects and increase product quality. This is regardless if you are a quality assurance specialist, factory manager, merchandiser, product designer, product developer or small fashion business owner,

The bottom line

Quality assurance in fashion is crucial since profits are involved due to factors such as delivery, defects and customer satisfaction. With high-quality products, a brand reputation can also be built which naturally results in higher revenue. Fewer defects also mean fewer refunds and/ or exchanges allowing a fashion firm to minimise additional costs in handling customer complaints and post-sales servicing.

There are a few things to keep in mind before choosing a course on quality assurance. While looking for an online course in this subject, it is necessary to make sure that the course is being organized by a trusted fashion school or institute.

Fashive provides fashion courses certified by the CPD certification service, a hallmark of quality. Our online courses can be done at a flexible pace allowing busy professionals to enhance their knowledge without fully committing to a full-time schedule. Check out our courses on areas such as quality assurance in the apparel industry and other online fashion courses taught by leading industry experts.